Our company

HengTai Group, one of the leading enterprises in China Carbon Industry, has been specializing in technology research and development, manufacturing and sales of graphite electrodes, carbon additive and other carbon products. Graphite electrodes are widely used in electric arc furnace and ladle furnace for steel production, ferroalloy production, silicon metal production and smelting processes. In addition to high temperature which can reach up to 3000ºC, our products are featured with higher electrical conductivity, stronger thermal shock resistance, higher mechanical strength, best chemical stability, higher oxidation resistance and lower consumption.

Dimensions for Graphite electrode conical nipples

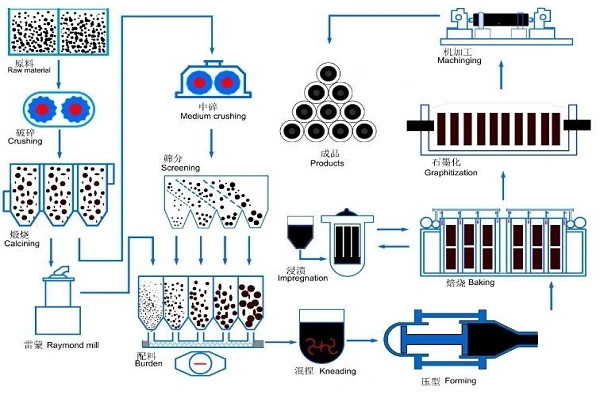

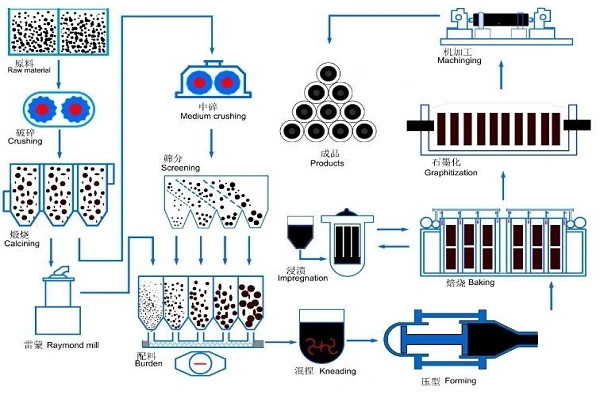

Hengtai Group has built the perfect carbon production processes including calcining, forming, baking, impregnation, graphitization and machining and also has advanced inspection and testing facilities and techniques. Our group has 24-pot calcinator, 3500 MT vacuumized oil hydraulic extrusion forming machine, 18-chamber ring baking furnace, high-pressure impregnation system, full CNC machine line and the first-class carbon inspection equipment.

The raw material (needle coke having a real density of 2.15g/cm3 and pore volume as measured with a mercury porosimeter of 0.136cc/g) is crushed with a jaw crusher and passed through a 8 to 16 mesh sieve followed by mixing the material on and below the sieve, crushing with a hammer crusher and sieving to sizes of 48 mesh to 200 mesh or smaller. In order to increase particle diameter, this needle coke is kneaded with binder pitch in two stages. The binder pitch had a softening point of 97ºC and β-resin content of 20%. Then, kneading is carried out for 20 minutes at 160ºC. After that, maintaining the same temperature, the second kneading goes on for 13 minutes. Following kneading, molding pressure is adjusted to a constant extrusion rate of 7cm/min with an extruder. Then the extruded electrodes are baked at 900ºC and then are in graphitization at 2500ºC.

The main products of Hengtai Group are from Φ75mm to 600mm RP, HP, UHP graphite electrodes with annual output of 50,000 tons, as well as high quality carbon additive and other graphite products.

How to Choose the Suitable Graphite Electrode Type:

If the Current Density is less than 17 A/cm2, you can choose RP. If the Current Density is between 18 and 25 A/cm2, you can choose HP. If the Current Density is above 25 A/cm2, UHP should be selected.

Allowable Current of RP/HP/UHP Graphite Electrodes

Instructions of usage for Graphite Electrode:

2. To Place the nipples, first use compressed air to clean the hole, then carefully screwed the nipples into it (do not damage the thread).

FAQ

HengTai Group, one of the leading enterprises in China Carbon Industry, has been specializing in technology research and development, manufacturing and sales of graphite electrodes, carbon additive and other carbon products. Graphite electrodes are widely used in electric arc furnace and ladle furnace for steel production, ferroalloy production, silicon metal production and smelting processes. In addition to high temperature which can reach up to 3000ºC, our products are featured with higher electrical conductivity, stronger thermal shock resistance, higher mechanical strength, best chemical stability, higher oxidation resistance and lower consumption.

| High Quality RP,HP,UHP HengTai Graphite Electrodes | ||||||

| Item | Type | Unit | Graphite Electrode | |||

| RP | HP | UHP | ||||

| Φ75-Φ600mm | Φ200-Φ600mm | Φ300-Φ500mm | Φ550-Φ600mm | |||

| Typical Value | Typical Value | Typical Value | Typical Value | |||

| Electric Resistivity | Electrode | µ Ωm | 7.0-9.0 | 5.8-6.6 | 4.3-5.8 | 4.3-5.8 |

| Nipple | 4.0-4.5 | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 |

| Transverse Strength | Electrode | Mpa | 8.0-10.0 | 10.0-13.0 | 10.0-15 | 10.0-15 |

| Nipple | 19.0-22.0 | 20.0-23.0 | 20.0-24 | 22.0-26 | ||

| Elastic Modulus | Electrode | Gpa | 7.0-9.3 | 8.0-12.0 | 9.0-13.0 | 10.0-14 |

| Nipple | 12.0-14.0 | 14.0-16.0 | 15.0-18 | 16.0-19 | ||

| Bulk Density | Electrode | g/cm3 | 1.60-1.66 | 1.66-1.68 | 1.68-1.7 | 1.7-1.76 |

| Nipple | 1.70-1.74 | 1.75-1.80 | 1.78-1.8 | 1.8-1.84 | ||

| Coefficient Thermal Expansion | Electrode | ×10-6/ºC | 2.2-2.6 | 1.6-1.9 | 1.1-1.4 | 1.1-1.4 |

| Nipple | 2.0-2.5 | 1.1-1.4 | 0.5-1.2 | 0.5-1.2 | ||

| Ash | % | 0.3 | 0.3 | 0.3 | 0.3 |

Dimensions for Graphite electrode conical nipples

| Dimensions for Graphite electrode | conical nipples | socket plug | screw pitch | ||||||

| D | d2 | L | I | d1 | H | ||||

| deviation | ≤ | deviation | |||||||

| type | metric system | British system | -0.30-0 | -0.30 0 | -1- 0 | 7 | 0-0.3 | 0-7 | 8.47 |

| 3TPI | 225 | 9″ | 139.7 | 91.22 | 203.2 | 141.22 | 107.6 | ||

| 250 | 10″ | 155.57 | 104.2 | 220 | 157.09 | 116 | |||

| 300 | 12″ | 177.16 | 117.39 | 270.9 | 148.68 | 141.5 | |||

| 350 | 14″ | 215.9 | 150.48 | 304.8 | 217.42 | 158.4 | |||

| 400 | 16″ | 215.9 | 150.48 | 304.8 | 217.42 | 158.4 | |||

| 400 | 16″ | 241.3 | 170.23 | 338.7 | 242.82 | 175.3 | |||

| 450 | 18″ | 241.3 | 170.23 | 338.7 | 242.82 | 175.3 | |||

| 450 | 18″ | 273.05 | 199.17 | 355.6 | 274.57 | 183.8 | |||

| 500 | 20″ | 273.05 | 199.17 | 355.6 | 274.57 | 183.8 | |||

| 500 | 20″ | 298.45 | 221.73 | 372.6 | 299.97 | 192.2 | |||

| 550 | 22″ | 298.45 | 221.73 | 372.6 | 299.97 | 192.2 | |||

| 600 | 24″ | 336.55 | 245.73 | 457.3 | 338.07 | 234.6 | |||

| 3TPIL | 350 | 14″ | 215.9 | 144.85 | 338.7 | 217.42 | 175.3 | ||

| 400 | 16″ | 241.3 | 167.43 | 355.6 | 242.82 | 183.8 | |||

| 450 | 18″ | 273.05 | 182.23 | 457.3 | 274.57 | 234.6 | |||

| 4TPI | 200 | 8″ | 122.24 | 81.48 | 177.8 | 7 | 115.92 | 94.9 | 6.35 |

| 225 | 9″ | 139.7 | 98.94 | 177.8 | 133.38 | 94.9 | |||

| 250 | 10″ | 152.4 | 109.52 | 190.5 | 146.08 | 101.3 | |||

| 300 | 12″ | 177.8 | 130.69 | 215.9 | 171.48 | 114 | |||

| 350 | 14″ | 203.2 | 149.74 | 254 | 196.88 | 133 | |||

| 400 | 16″ | 222.25 | 160.32 | 304.8 | 215.93 | 158.4 | |||

| 450 | 18″ | 241.3 | 197.37 | 304.8 | 234.98 | 158.4 | |||

| 500 | 20″ | 269.88 | 199.49 | 355.6 | 263.56 | 183.8 | |||

| 550 | 22″ | 298.45 | 228.06 | 355.6 | 292.13 | 183.8 | |||

| 600 | 24″ | 317.5 | 247.11 | 355.6 | 311.18 | 183.8 | |||

| 650 | 26″ | 355.6 | 268.27 | 457.2 | 349.28 | 234.6 | |||

| 700 | 28″ | 374.65 | 287.32 | 457.2 | 368.33 | 234.6 | |||

| 4TPIL | 300 | 12″ | 177.8 | 124.34 | 254 | 171.48 | 133 | ||

| 350 | 14″ | 203.2 | 141.27 | 304.8 | 196.88 | 158.4 | |||

| 400 | 16″ | 222.25 | 151.86 | 355.6 | 215.93 | 183.8 | |||

| 450 | 18″ | 241.3 | 190.91 | 355.6 | 234.98 | 183.8 | |||

| 500 | 20″ | 269.88 | 182.55 | 457.2 | 263.56 | 234.6 | |||

| 550 | 22″ | 298.45 | 211.12 | 457.2 | 292.13 | 234.6 | |||

| 600 | 24″ | 317.5 | 230.17 | 457.2 | 311.18 | 234.6 | |||

| 650 | 26″ | 355.64 | 251.38 | 558.8 | 349.28 | 285.4 | |||

| 700 | 28″ | 374.65 | 370.39 | 588.8 | 368.33 | 285.4 | |||

Hengtai Group has built the perfect carbon production processes including calcining, forming, baking, impregnation, graphitization and machining and also has advanced inspection and testing facilities and techniques. Our group has 24-pot calcinator, 3500 MT vacuumized oil hydraulic extrusion forming machine, 18-chamber ring baking furnace, high-pressure impregnation system, full CNC machine line and the first-class carbon inspection equipment.

The raw material (needle coke having a real density of 2.15g/cm3 and pore volume as measured with a mercury porosimeter of 0.136cc/g) is crushed with a jaw crusher and passed through a 8 to 16 mesh sieve followed by mixing the material on and below the sieve, crushing with a hammer crusher and sieving to sizes of 48 mesh to 200 mesh or smaller. In order to increase particle diameter, this needle coke is kneaded with binder pitch in two stages. The binder pitch had a softening point of 97ºC and β-resin content of 20%. Then, kneading is carried out for 20 minutes at 160ºC. After that, maintaining the same temperature, the second kneading goes on for 13 minutes. Following kneading, molding pressure is adjusted to a constant extrusion rate of 7cm/min with an extruder. Then the extruded electrodes are baked at 900ºC and then are in graphitization at 2500ºC.

The main products of Hengtai Group are from Φ75mm to 600mm RP, HP, UHP graphite electrodes with annual output of 50,000 tons, as well as high quality carbon additive and other graphite products.

What is an Electric Arc Furnace

An Electric Arc Furnace is essentially a giant heat-resistant kettle. The Electric Arc Furnace is more modern and can produce its product using scrap steel material, which is tossed into the furnace with the help of a large crane. A lid containing graphite electrodes is then placed on top of and lowered into the furnace, where they conduct an electric current which takes the shape on an arc. When power is fed into the furnace, the electricity jumps between the electrodes and grounded electrode. The high-voltage electric arcs created by these graphite electrodes give off large amounts of direct and radiant heat that melts the contents of the furnace. When the molten metal is ready for use, it can be drained through a special part on the furnace for casting and forging. The entire process can take as little as an hour.How to Choose the Suitable Graphite Electrode Type:

If the Current Density is less than 17 A/cm2, you can choose RP. If the Current Density is between 18 and 25 A/cm2, you can choose HP. If the Current Density is above 25 A/cm2, UHP should be selected.

Allowable Current of RP/HP/UHP Graphite Electrodes

| Type | Nominal Diameter(mm) | Allowable Current (A) | Current Density (A/cm2) |

| RP | 200-300 | 13000-17400 | ≤17 |

| HP | 350-600 | 17400-58000 | 18≤,≥25 |

| UHP | 350-700 | 58000-72000 | ≥25 |

Instructions of usage for Graphite Electrode:

Notes of usage:

1. The electrodes should be stored in the clean and dry places, and should be avoided for shock and collision. Before used, the electrodes should be baked to dry.

2. To Place the nipples, first use compressed air to clean the hole, then carefully screwed the nipples into it (do not damage the thread).

3. To connect the electrodes, when there's 20-30mm distance between the two electrodes, using compressed air to clean the two extremes.

4.When use the wrenches to connect electrodes, should be fully tighten to specified torque.

5.To avoid electrode broken, please remove the insulating material in the furnace.

6.To avoid electrode broken, please place the big block in the lower and smaller block at the upper.

FAQ

- What is your payment term?

In general, our company needs 30% TT the deposit and 70% TT the balance after seeing the copy of B/L. And our company also accepts 70% LC the balance. - Is your company a factory or a trade company?

Hengtai Group, one of the leading enterprises in China Carbon Industry, has been specializing in technology research and development, manufacturing and sales of graphite electrodes, carbon additive and other carbon products. We are a group. - What is your material?

Our company takes high quality petroleum coke and needle coke as raw material.

Mr. Tim