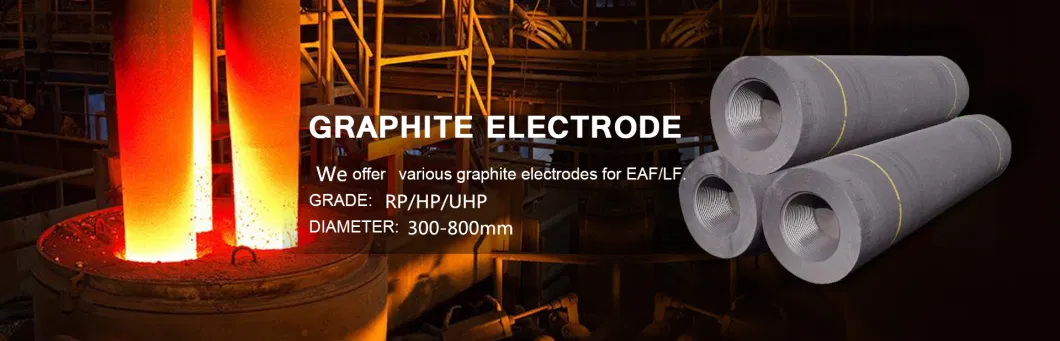

In the steelmaking process, iron scrap gets melted in an electric arc furnace and recycled. Graphite electrodes, a kind of conductor, are an essential component in this kind of furnace. They can melt scrap at a temperature of about 1600ºC.

Graphite Electrodes Varieties

1.For DC Furnaces (direct current furnaces) / Size: 22-32 inches

Electrodes for DC furnaces, which require 1 column of graphite electrodes. High maximum current density. The diameter of these electrodes is getting bigger: the current maximum diameter is 32 inches (800 mm).

2.For AC Furnaces (alternating current furnaces) / Size: 16-28 inches.

Alternating current furnaces require 3 columns of graphite electrodes. They mostly use 20-28 inch electrodes, the standard size in electric furnaces.

3.For LF Furnaces (refining furnaces) / Size: 10-18 inches

These electrodes are for refining materials like molten steel. LF Furnaces have a smaller capacity than DC.

Productive process

Specification

Properties | Unit | UHP | HP | RP | ||

300-600mm | 650-800mm | 300-800mm | 300-800mm | |||

Electric resistivity | Electrode | μΩm | 4.8-5.8 | 4.6-5.8 | 5.8-6.6 | 7.8-8.8 |

Nipple | 3.8-4.5 | 3.8-4.5 | 4.2-5.0 | 5.0-6.5 | ||

Flexural strength | Electrode | Mpa | 10.0-14.0 | 10.0-14.0 | 10.0-13.0 | 7.0-12.0 |

Nipple | 20.0-26.0 | 22.0-26.0 | 18.0-22.0 | 15.0-20.0 | ||

Young's modulus | Electrode | Gpa | 9.0-13.0 | 10.0-14.0 | 8.0-12.0 | 7.0-9.3 |

Nipple | 15.0-18.0 | 15.0-18.0 | 14.0-16.0 | 12.0-14.0 | ||

Bulk density | Electrode | ≥g/cm3 | 1.68-1.74 | 1.70-1.74 | 1.62-1.66 | 1.53-1.56 |

Nipple | 1.77-1.82 | 1.78-1.84 | 1.74-1.80 | 1.70-1.74 | ||

CTE(100-600ºC) | Electrode | x10-6/ºC | 1.1-1.4 | 1.1-1.4 | 1.6-1.9 | 2.2-2.6 |

Nipple | 0.9-1.2 | 0.9-1.2 | 1.1-1.4 | 2.0-2.5 | ||

Ash | 0.3 | 0.3 | 0.3 | 0.5 | ||

Size/Weight Chart

| Name | Pole diameter | Pole length | Pole weight (reference value) | |||

| Diameter x length | Maximum | Minimum | Maximum | Minimum | Pole product weight (excluding nipple) | |

| inch | mm | mm | mm | mm | mm | kg |

| 14×60 | 350×1500 | 357 | 352 | 1550 | 1400 | 253 |

| 14×72 | 350×1800 | 1875 | 1700 | 304 | ||

| 14×96 | 350×2400 | 2475 | 2275 | 406 | ||

| 16×60 | 400×1500 | 409 | 403 | 1550 | 1400 | 334 |

| 16×72 | 400×1800 | 1875 | 1700 | 395 | ||

| 16×96 | 400×2400 | 2475 | 2275 | 532 | ||

| 18×72 | 450×1800 | 460 | 454 | 1875 | 1700 | 496 |

| 18×96 | 450×2400 | 2475 | 2275 | 665 | ||

| 18×110 | 450×2700 | 2850 | 2550 | 766 | ||

| 20×72 | 500×1800 | 511 | 505 | 1875 | 1700 | 614 |

| 20×84 | 500×2100 | 2175 | 1975 | 715 | ||

| 20×96 | 500×2400 | 2475 | 2275 | 824 | ||

| 20×110 | 500×2700 | 2850 | 2550 | 927 | ||

| 22×84 | 550×2100 | 562 | 556 | 2175 | 1975 | 873 |

| 22×96 | 550×2400 | 2475 | 2275 | 995 | ||

| 24×84 | 600×2100 | 613 | 607 | 2175 | 1975 | 1040 |

| 24×96 | 600×2400 | 2475 | 2275 | 1190 | ||

| 24×110 | 600×2700 | 2850 | 2550 | 1340 | ||

| 26×110 | 650×2700 | 663 | 657 | 2850 | 2550 | 1580 |

| 28×110 | 700×2700 | 714 | 708 | 2850 | 2550 | 1830 |

| 30×110 | 750×2700 | 765 | 759 | 2850 | 2550 | 2060 |

| 32×110 | 800×2700 | 816 | 810 | 2850 | 2550 | 2450 |

Application

Graphite electrodes are widely used for production of alloy steels, metal and other nonmetallic materials, etc.

- DC electric arc furnace

- AC electric arc furnace

- Submerged arc furnace

- Ladle furnace

Eccentric bottom tapping electric furnace Graphite electrode for vacuum ladle furnace Graphite electrode for electric arc furnace

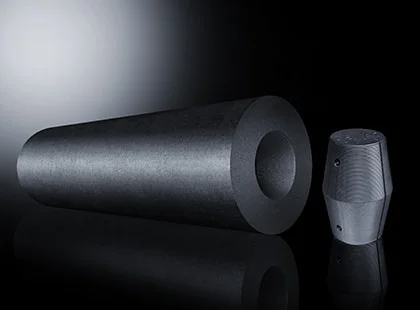

Products

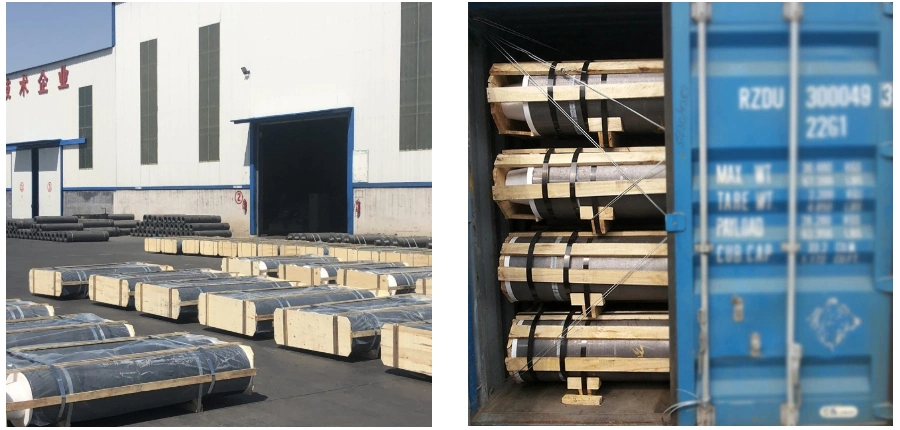

Packing and delivering

Contact us