Product Name | Corrosion Resistance High Quality Refractory Alumina Laboratory Ceramic Crucible Tray |

Material | Alumina |

Color | Ivory |

Size | 150*50*10mm |

Content | 99% al2o3 |

Payment | T/T,Western Union,Online payment by credit card are available |

Application | it is widely used for sintering furnace. |

Thransport | Air transport: 5-10 days; Ocean shipping: About one month. |

Delivery Time | 1.Stock:delivery within 3-5 days after receiving your payment. 2. OEM/ODM:The normal Lead time is 15-45 days, which depends on your quantiy. |

Corrosion Resistance High Quality Refractory Alumina Laboratory Ceramic Crucible Tray

We make 99.7%Al2O3 crucibles and boats, which max working temperature is 1800ºC and 95% Al2O3 crucibles and boats, which max working temperature is 1500ºC.

Crucible capacity from 0.5ml to 10000ml. very big sized can be made as your design.

We have cylindrical type crucibles, conical type crucibles, boat and other special shaped crucibles or boats according to your design.

Our Advantages

1.High purity, 99.5% alumina purity makes sure high working temperature.

2.Large quantity mould in stock, you will find a suitable one.

3.Very small and very big sized ones can be made.

4.Inspection: each single crucible and boat will be checked before shipping.

5.Low transportation cost. We have long time cooperated shipping agency, which can provide very low prices.

| Cylindrical Shape | ||||||||||

| OD (mm) | 25 | 36 | 41 | 50 | 60 | 45 | 62 | 50 | 125 | 172 |

| ID (mm) | 20 | 25 | 35 | 46 | 55 | 40 | 58 | 45 | 115 | 159 |

| Height (mm) | 25 | 59 | 41 | 60 | 60 | 110 | 74 | 140 | 145 | 152 |

| Capacity (ml) | 7 | 26 | 40 | 90 | 130 | 135 | 165 | 215 | 1400 | 3000 |

| Conical Shape | ||||||||||

| Top OD (mm) Buttom OD(mm) | 34 28.5 | 34 20 | 40 22 | 50 30 | 60 40 | 78 46 | 100 77 | 95 85 | 90 40 | 120 77 |

| ID (mm) | 23.5 | 29 | 36 | 46 | 56 | 74 | 94 | 85 | 82 | 108 |

| Height (mm) | 33 | 40 | 48 | 50 | 70 | 90 | 80 | 110 | 130 | 160 |

| Capacity (ml) | 15 | 20 | 40 | 65 | 130 | 300 | 400 | 500 | 600 | 1400 |

| Alumina Boat | ||||||||||

| Length (mm) | 30 | 50 | 65 | 100 | 100 | 300 | 200 | 300 | 100 | 250 |

| Width (mm) | 20 | 10 | 55 | 20 | 50 | 36 | 100 | 36 | 100 | 100 |

| Height (mm) | 15 | 10 | 65 | 20 | 30 | 18 | 50 | 18 | 17.5 | 70 |

Datasheet

Item | Unit Symbol | 95% Alumina Ceramics | 99% Alumina Ceramics | 99.7% Alumina Ceramics |

Maximum Using Temperature | ºC | 1600 | 1700 | 1700 |

Water Absorption | % | 0 | 0 | 0 |

Hardness | Gpa | ≥85 | ≥89 | ≥89 |

Flexural Strength | MPa (psi x 103) | 336 | 550 | 550 |

Compressive Strength | MPa (psi x 103) | 2000 | 2500 | 2500 |

Fracture Toughness | Mpa | 4~5 | 5.6 | 6 |

Thermal Conductivity | W/m °K | 18-25 | 30 | 30.4 |

Thermal Shock Resistance | °C | 220 | 180-220 | 180-220 |

Dielectricity Constant | 9.4 | 9.8 | 9.8 |

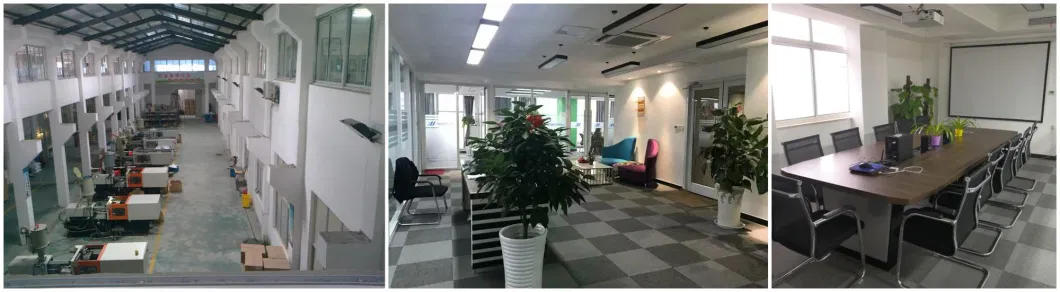

Is a leading high-tech ceramic development and production enterprises.

Our ceramic products are widely used in various fields of automotive, metallurgy, machinery, electronic & electrical, food, chemical, medical and so on. With experienced engineers and talented workers, we are able to evaluate projects and drawings properly, make valuable suggestion, supply satisfying products. Our materials including:

- Alumina ceramic tube, alumina parts( 95% 96% 99% 99.5% 99.7% Al2O3 )

- Zirconia cermaic ( Yttria stabilized ZrO2 )

- Silicon Nitride ( GPS Gas pressure sintered & Hot pressed Si3N4 )

- Silicon carbide

- Boron Carbide ( B4C )

- Boron Nitride ( Hot pressed BN )

- Machinable Glass Ceramic

- Steatite, cordierite

Q:Are you a trading company or a manufacturer?

A:We are professional manufacturer which has almost 10 years of experience in this industry.

Q:Can you produce according to the samples?

A:Yes,we can produce by your samples or technical drawings.

Q:Would it be possible for us to visit your factory?

A:Sure,we welcomed our customers visit our factory in any time.

Q:Will your company supply samples?

A:Yes,the sample expense will be deducted from the value of your order.

Q:What's your payment terms?

A:T/T, L/C, Western Union, Money Gram, are available for us.

Q:Delivery time for my order?

A:Within 7-15 working days for your sample order; 20 working days for your bulk order( It depends on the models and quantity you are going to order)